machine

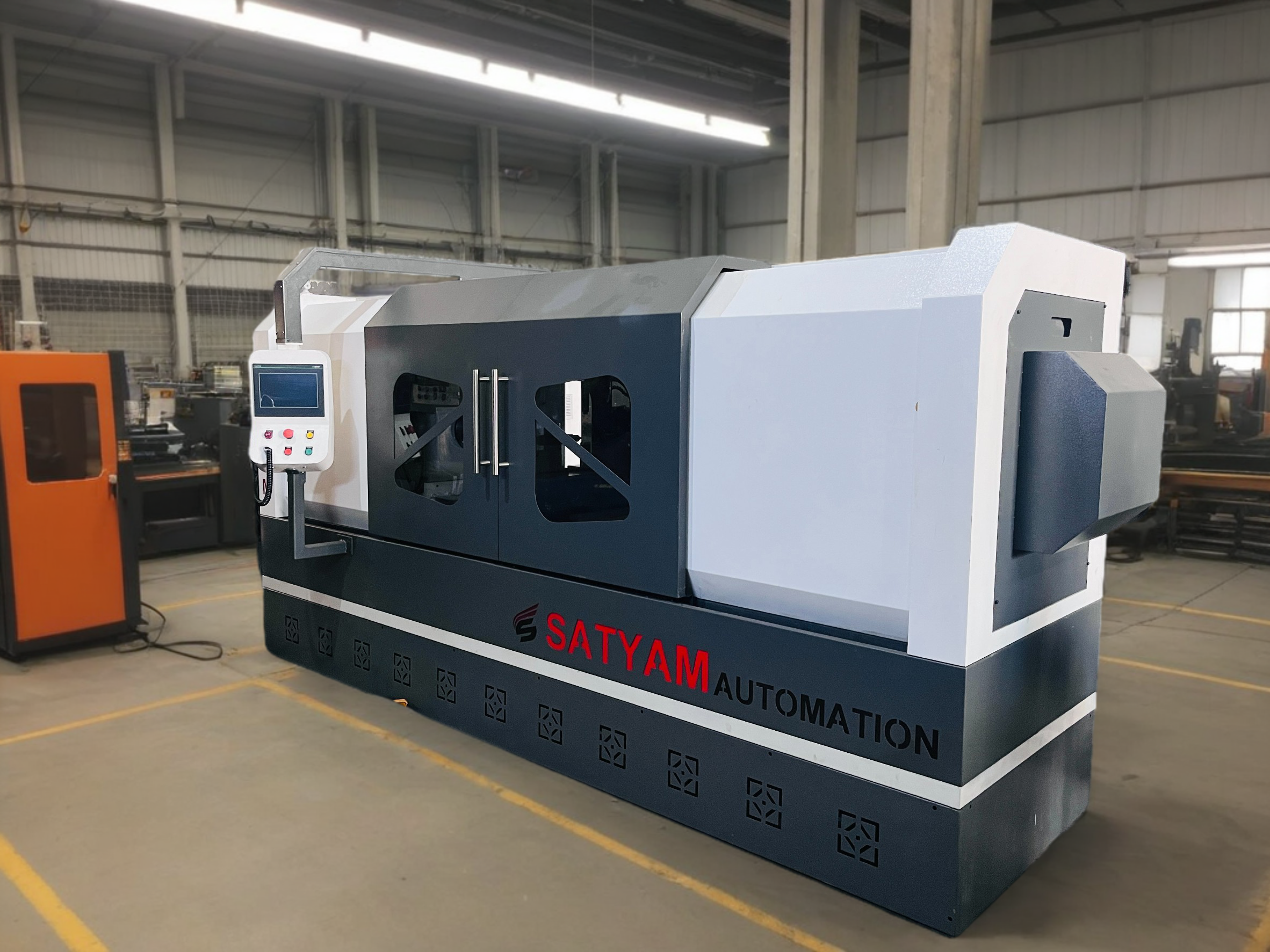

SATYAM AUTOMATION AUTOLODER DRILLING MACHINE , HANDEL LOCK PISTON DRILLING MACHINE, VIDEO YOUTUBE CHANEL SATYAM AUTOMATION

An autoloader drilling machine is an industrial equipment designed to automate the loading and unloading of materials into a drilling machine for precise and efficient drilling operations. The manufacturing process of such machines involves a combination of mechanical, electrical, and automation components. Below is an outline of the steps involved in manufacturing an autoloader drilling machine:

1. Design and Engineering

Conceptualization: The design team begins by understanding the application, material requirements, and automation needs. They will consider factors like drilling depth, speed, precision, and material handling capacity.

CAD Design: Engineers use CAD (Computer-Aided Design) software to create detailed blueprints and models of the autoloader drilling machine. This includes mechanical components (drill head, spindle, frame), electrical systems (motors, sensors, control units), and automation elements (robots or conveyors for material loading and unloading).

Prototype Development: A prototype or a pilot model is built to test and validate the design. This helps in assessing the feasibility and any potential issues before full-scale manufacturing.

2. Procurement of Raw Materials

Structural Materials: High-strength steel, aluminum, or other metals are used for building the frame and base structure.

Components for Drilling Mechanism: Drill bits, spindles, and other consumables used in the drilling process are sourced.

Automation Components: Motors, servos, and robotic arms for autoloading mechanisms are procured from automation suppliers.

Electrical Components: Control panels, wiring, sensors, PLCs (Programmable Logic Controllers), and other electronic parts are bought from specialized vendors.

3. Fabrication of Parts

Frame Construction: The structural frame of the machine is fabricated from steel or other materials. This frame holds all the components and supports the weight during operations.

Drill Head and Spindle Assembly: The drill head, spindle, and other critical components are manufactured or sourced from suppliers. Precision machining and balancing are important at this stage to ensure smooth and accurate drilling operations.

Automation System Assembly: The autoloader mechanism involves robotic arms or conveyors to automatically load the material onto the drill and unload it after drilling. Components like motors, actuators, and sensors are integrated into this system.

4. Assembly of Components

Mechanical Assembly: The frame, drill head, and other mechanical components are assembled together, ensuring precise alignment and smooth operation.

Electrical Wiring: The electrical components such as motors, PLC systems, control panels, and sensors are connected to the machine.

Autoloader Integration: The autoloader mechanism (such as robotic arms or conveyor systems) is integrated with the drilling system. This involves setting up the automation control systems that coordinate the movement of materials into and out of the drill.

PLC Programming: The machine’s programmable logic controller (PLC) is programmed to control the operation of the drilling machine and autoloader system. This will include automating processes like material loading, drilling speed, and unloading, ensuring consistent production.

5. Testing and Quality Control

Operational Testing: The assembled machine undergoes rigorous testing. The machine’s functionality, including material loading, drilling, and unloading, is thoroughly tested.

Precision Checks: The accuracy of drilling is verified, ensuring that holes are drilled at the right depth and location with minimal deviation.

Automation System Check: The autoloader is checked for reliability, ensuring that the material is accurately loaded, drilled, and unloaded without any errors or delays.

Safety Checks: Safety features, including emergency stop mechanisms, safety shields, and sensor systems, are tested to ensure compliance with industry safety standards.

Send Message