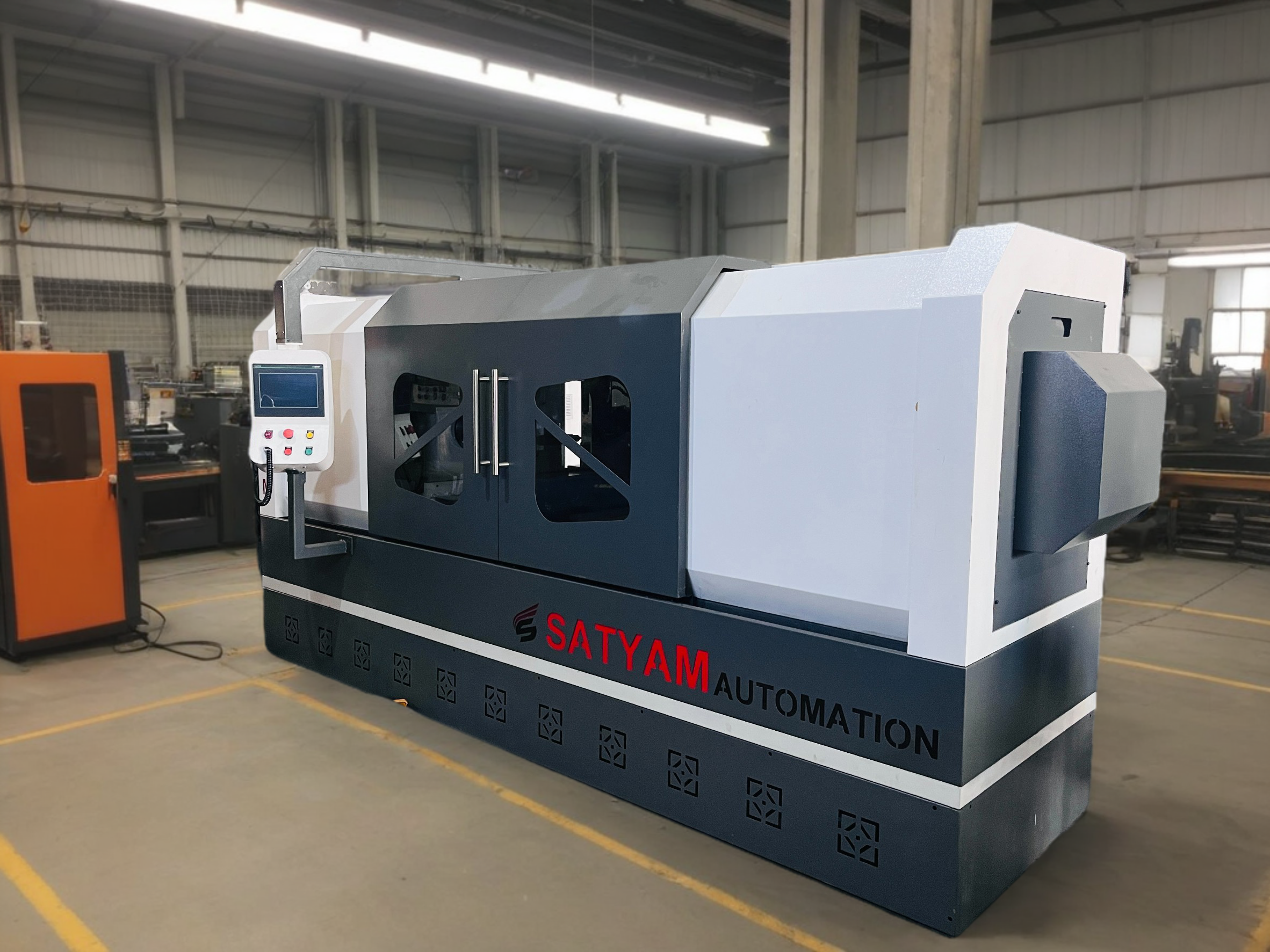

Title: "Revolutionizing the Valve Industry: The Gate Valve Turning Machine" In the world of industrial machinery, innovation and efficiency are paramount. One such innovation making waves in the valve industry is the Gate Valve Turning Machine. This cutting-edge technology is revolutionizing the way gate valves are manufactured and operated, providing numerous benefits for companies in the industry. What is a Gate Valve Turning Machine, you may ask? Simply put, it is a specialized piece of equipment designed to automate the process of turning gate valves. Gate valves are commonly used in a variety of industries, including oil and gas, water treatment, and manufacturing. Traditionally, turning these valves required significant manual labor, time, and effort. However, the Gate Valve Turning Machine streamlines this process, allowing for quicker and more precise operation. One of the key advantages of the Gate Valve Turning Machine is its efficiency. By automating the turning process, companies can significantly reduce the time and labor required to operate gate valves. This not only saves money but also increases productivity and allows for more consistent and precise valve operation. Additionally, the Gate Valve Turning Machine can improve worker safety. Manual valve turning can be a hazardous task, especially in high-pressure or high-temperature environments. By utilizing the Gate Valve Turning Machine, companies can reduce the risk of accidents and injuries, creating a safer work environment for their employees. In terms of industry competitiveness, the Gate Valve Turning Machine can give companies a significant edge. By investing in this advanced technology, companies can increase their production capacity, improve the quality of their products, and ultimately enhance their reputation within the industry. Overall, the Gate Valve Turning Machine is a game-changer for the valve industry. Its efficiency, safety benefits, and competitive advantages make it a valuable investment for companies looking to stay ahead in today's fast-paced industrial market. As technology continues to evolve, the Gate Valve Turning Machine represents the future of valve manufacturing and operation.

Send Message