Title: Dive into Efficiency: The Submersible Body Turning/Threading and Grooving Machine

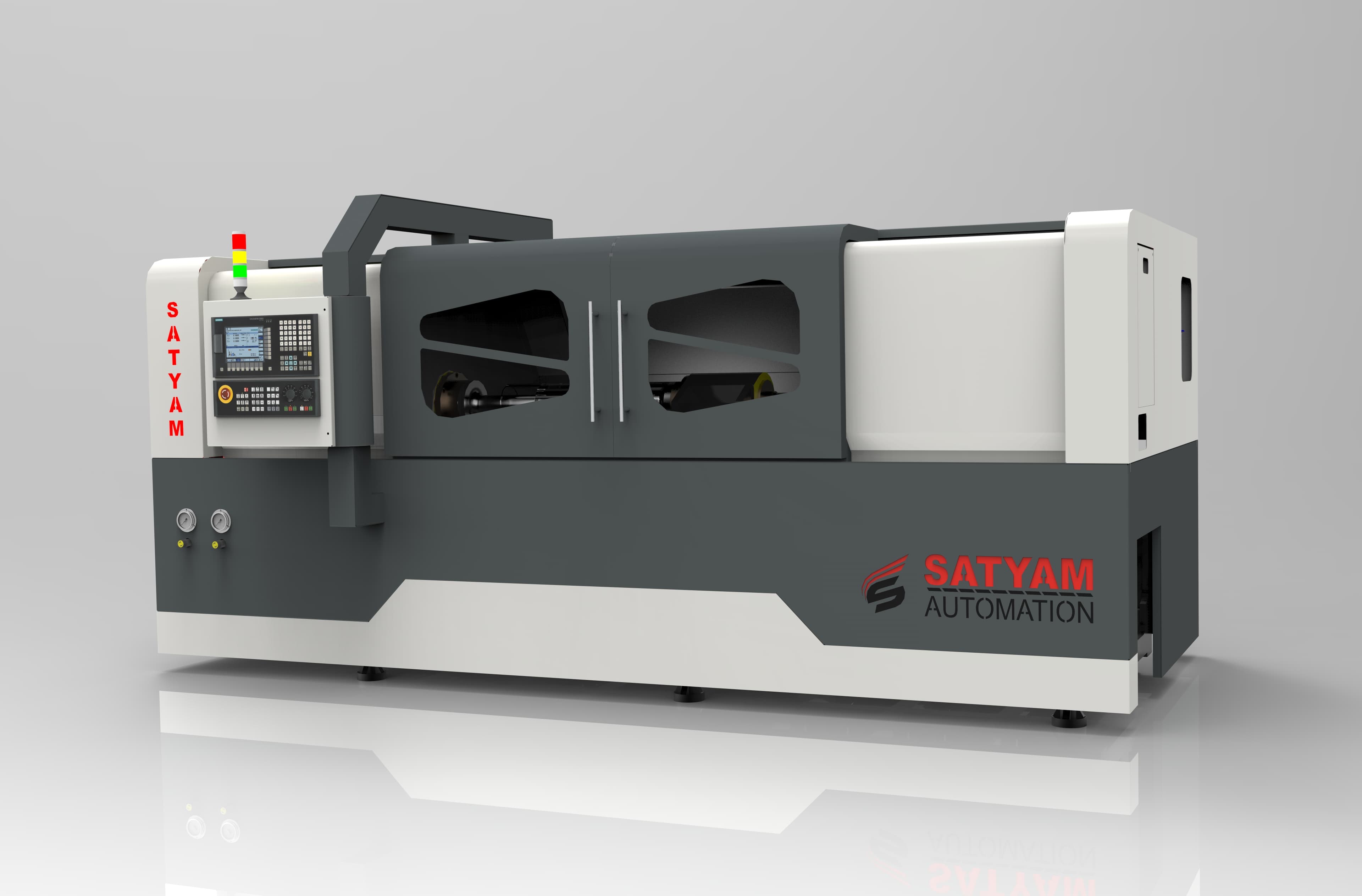

Are you tired of spending hours upon hours manually turning, threading, and grooving pipes and tubing? Look no further than the Submersible Body Turning/Threading and Grooving Machine. This innovative piece of equipment is revolutionizing the way industries handle pipe fabrication, offering a quicker, more efficient, and more precise solution.

The Submersible Body Turning/Threading and Grooving Machine is designed to streamline the production process, making it easier than ever to create high-quality, precise threads and grooves. By submerging the body of the pipe in water, the machine is able to achieve cleaner cuts and reduce the risk of heat deformation. This results in stronger, more reliable connections that are essential for any project.

One of the key benefits of this machine is its versatility. Whether you're working with steel, copper, PVC, or any other type of material, the Submersible Body Turning/Threading and Grooving Machine is up to the task. It can handle a wide range of pipe sizes and diameters, making it ideal for a variety of applications.

Not only does this machine offer superior efficiency and precision, but it also helps to improve workplace safety. By automating the turning, threading, and grooving process, employees can avoid the risks associated with manual labor, reducing the chance of injury and improving overall productivity.

In conclusion, the Submersible Body Turning/Threading and Grooving Machine is a game-changer for industries that rely on precise pipe fabrication. Its ability to streamline production, improve accuracy, and enhance safety makes it a must-have tool for any workshop or factory. Say goodbye to manual labor and hello to efficiency with this innovative machine.

Keywords

way

PVC

tool

risk

task

pipes

water

hours

steel

Title

chance

injury

tubing

copper

variety

project

grooves

factory

ability

goodbye

material

workshop

accuracy

diameters

equipment

precision

employees

other type

wide range

pipe sizes

industries

conclusion

versatility

manual labor

key benefits

game-changer

cleaner cuts

applications

precise solution

innovative piece

workplace safety

grooving process

Grooving Machine

heat deformation

innovative machine

production process

superior efficiency

reliable connections

overall productivity

precise pipe fabrication

high-quality, precise threads

The Submersible Body Turning/Threading