Unlocking Potential: The Power of CNC Machines in Modern Manufacturing

CNC machines have transformed how we think about manufacturing. From intricate designs to high-volume production, these machines bring precision and efficiency to the forefront. This article explores various types of CNC machines, especially focusing on the CNC Lathe Bed Machine, Dual Spindle Mini VMC, and other essential tools.

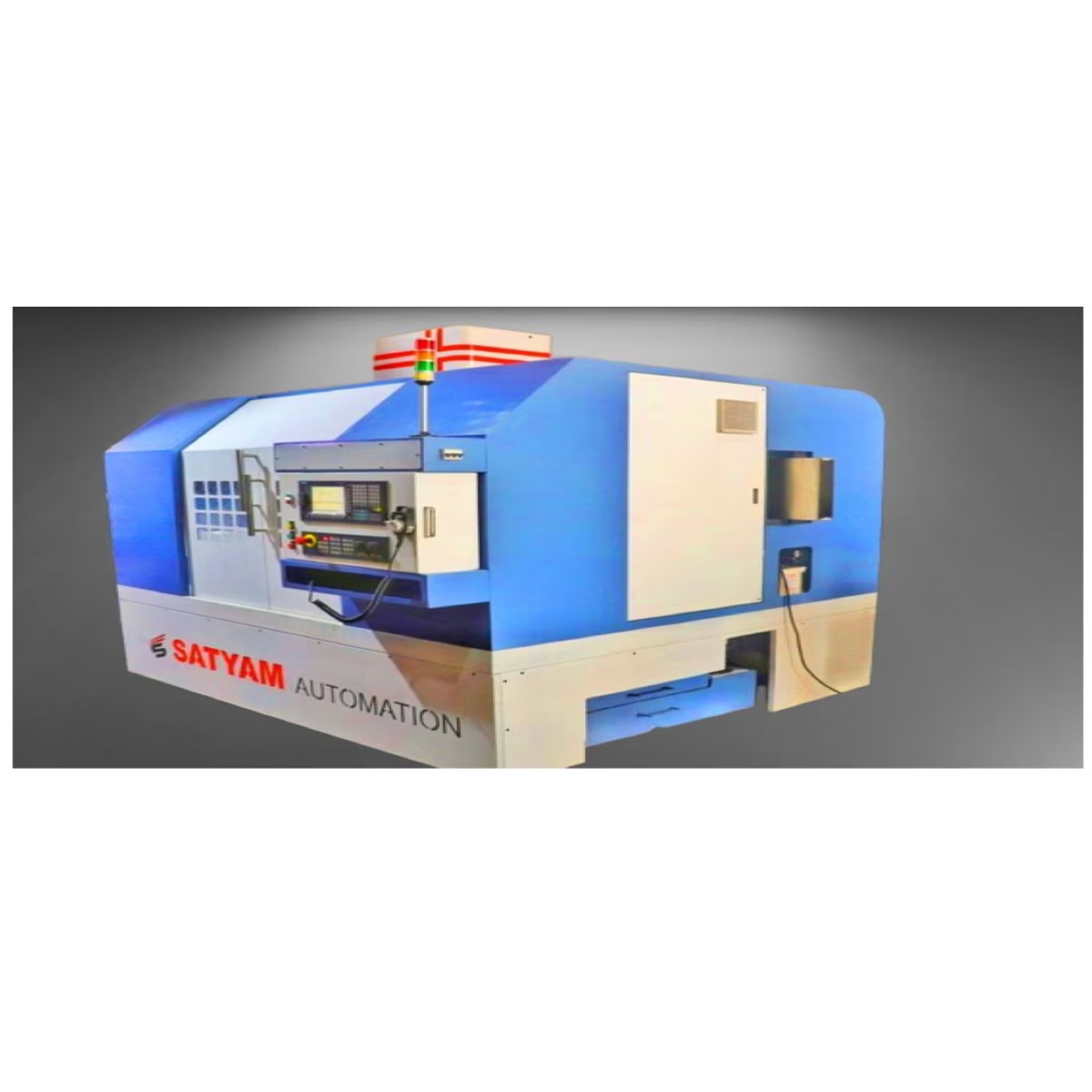

What is a CNC Lathe Bed Machine?

A CNC Lathe Bed Machine is a vital piece of equipment in manufacturing. It’s like having a sculptor who can carve designs from blocks of material. This machine spins the workpiece while the tools cut it to shape. The result? Accurate, consistent parts made quickly and efficiently. It’s a useful tool for making everything from simple rods to complex shapes.

Exploring the Dual Spindle Mini VMC

The Dual Spindle Mini VMC (Vertical Machining Center) stands out in its ability to multitask. Imagine having two workers doing the job of one! This machine has two spindles, allowing it to work on two parts at once. This feature doubles productivity without compromising quality. Businesses see quicker turnaround times, which means happier customers and better profits.

The Importance of CNC SPM Machines

CNC SPM Machines, or Special Purpose Machines, focus on specific tasks. Think of them as the Swiss Army knives of manufacturing. They can handle a variety of functions, whether it’s drilling, milling, or turning. Because these machines are designed for specialized tasks, they often increase efficiency and accuracy. Perfect for high-demand production settings, they help reduce downtime and human error.

Micro Drilling Machines: Precision at Its Finest

Micro Drilling Machines tackle tasks that require extreme precision. These specialized tools can drill tiny holes in materials, which is essential in industries like electronics and medical devices. It’s like using a tiny needle to create intricate designs in a larger canvas. With these machines, even the smallest components can be produced with incredible accuracy.

Benefits of Automatic Lathe Machines

Automatic Lathe Machines simplify the manufacturing process. These machines are designed to automate repetitive tasks, making them ideal for high-volume production. Instead of human operators watching every step, these machines run on their own. This not only increases efficiency but also lessens the chance of mistakes.

The Role of Dual Spindle Drill Machines

Dual Spindle Drill Machines take productivity to a new level. With two spindles, these machines can drill and tap at the same time. This dual-action capability saves time and boosts output. It’s like having a multi-tasking employee who can handle two jobs simultaneously, resulting in faster production cycles and reduced labor costs.

Flat Bed Turning Machine: Versatility in Action

The Flat Bed Turning Machine is known for its versatility in manufacturing. This machine is capable of producing a wide range of parts, from simple to complex. It can handle various materials, making it suitable for different industries. With adjustable settings and robust performance, it’s an essential tool for any workshop looking to maximize its capabilities.

The Importance of CNC Gate Valve Turning

CNC Gate Valve Turning is crucial for industries requiring precise valve manufacturing. These machines produce high-quality valves essential for waterworks, oil, and gas. The accuracy offered by CNC technology ensures that these valves function correctly under pressure. Outdated methods can lead to leaks and failures. With CNC Gate Valve Turning, companies can ensure reliability and safety.

Conclusion: CNC Machines as the Backbone of Manufacturing

CNC machines like the Lathe Bed, VMC, and SPM are no longer just tools; they are the backbone of modern manufacturing. Their ability to produce high-quality parts quickly and efficiently allows industries to thrive. Whether it’s micro drilling, automated lathes, or dual spindle machines, the benefits are clear. Embracing these technologies means businesses can stay competitive and innovative, paving the way for a brighter future.

Keywords

two jobs

same time

new level

two parts

wide range

tiny holes

labor costs

tiny needle

human error

two workers

simple rods

useful tool

vital piece

two spindles

CNC Machines

larger canvas

various types

specific tasks

complex shapes

CNC technology

brighter future

human operators

medical devices

repetitive tasks

Outdated methods

CNC SPM Machines

extreme precision

various materials

intricate designs

specialized tools

specialized tasks

happier customers

Swiss Army knives

high-quality parts

robust performance

incredible accuracy

high-quality valves

smallest components

Unlocking Potential

adjustable settings

different industries

Modern Manufacturing

manufacturing process

other essential tools

dual spindle machines

multi-tasking employee

dual-action capability

high-volume production

CNC Gate Valve Turning

Micro Drilling Machines

A CNC Lathe Bed Machine

Special Purpose Machines

faster production cycles

Automatic Lathe Machines

quicker turnaround times

Vertical Machining Center

The Dual Spindle Mini VMC

Accurate, consistent parts

precise valve manufacturing

Dual Spindle Drill Machines

The Flat Bed Turning Machine

high-demand production settings